Colle de Cologne - CDC

Renia CDC Video

CDC Renia Sheet

MATERIALS: Leather, rubber, EVA, TPR, PU, PVC and cork. And most materials shoes are made from.

INSTRUCTIONS: Grind materials and coat them with CDC until you can see a layer of cement.

TPR (Thermoplastic Rubber): Apply Rehagol, wait 5 minutes and apply CDC

PUR (Polyurethane): Grind, if wet sole press the material with paper towels to remove the water. Primer for PUR can be used for very soft polyurethane. Or try 2 coats of CDC.

Hard plastics PE, PP Orthotics: Contact with an open gas flame then coat with glue immediately.

ASSEMBLY TIME: It depends on the material: Cold or heated. Generally 5 - 30 minutes. After that needs briefly heating.

TPR 3-15 minutes, PVC 10 - 45 minutes

PRESSURE: 1 - 5 bar (15-60 psi) depending on the material 1 bar (15 psi) minimum time 60 seconds, 3 bar minimum time 15 seconds. The softer the material the less pressure you need.

Caution: Do not deform materials during pressing; otherwise the adhesive film will be destroyed. And don't hammer soft materials with great violence else glue layer will be destroyed.

STRENGTH: The glue-power increases continuously during the first two days. For work boots etc adding 5- 10 % hardener, will get the best resistance against heat, oil and other chemical influences. Same for gluing PVC to PVC or bonding natural rubber.

CDC Renia Sheet

MATERIALS: Leather, rubber, EVA, TPR, PU, PVC and cork. And most materials shoes are made from.

INSTRUCTIONS: Grind materials and coat them with CDC until you can see a layer of cement.

TPR (Thermoplastic Rubber): Apply Rehagol, wait 5 minutes and apply CDC

PUR (Polyurethane): Grind, if wet sole press the material with paper towels to remove the water. Primer for PUR can be used for very soft polyurethane. Or try 2 coats of CDC.

Hard plastics PE, PP Orthotics: Contact with an open gas flame then coat with glue immediately.

ASSEMBLY TIME: It depends on the material: Cold or heated. Generally 5 - 30 minutes. After that needs briefly heating.

TPR 3-15 minutes, PVC 10 - 45 minutes

PRESSURE: 1 - 5 bar (15-60 psi) depending on the material 1 bar (15 psi) minimum time 60 seconds, 3 bar minimum time 15 seconds. The softer the material the less pressure you need.

Caution: Do not deform materials during pressing; otherwise the adhesive film will be destroyed. And don't hammer soft materials with great violence else glue layer will be destroyed.

STRENGTH: The glue-power increases continuously during the first two days. For work boots etc adding 5- 10 % hardener, will get the best resistance against heat, oil and other chemical influences. Same for gluing PVC to PVC or bonding natural rubber.

Syntic Total

Renia Syntic Video

Syntic Renia Sheet

Strong, Clear, PU based, most like Bostik 999 or 777.

Great for Half soles, Unit soles.

Rehagol Primer for TPR/TPU, EVA6 for some EVA

Limitations - Some cheap EVA's. Works fine on Caster, don't over heat.

Syntic Renia Sheet

Strong, Clear, PU based, most like Bostik 999 or 777.

Great for Half soles, Unit soles.

Rehagol Primer for TPR/TPU, EVA6 for some EVA

Limitations - Some cheap EVA's. Works fine on Caster, don't over heat.

Ortec

Renia Ortec Video

Not that strong, Yellow, PC based (polychloroprene cement) , basically Neoprene? most like Bostik 1222

Great for standard heels, leather to leather, putting zips in and anything that needs stitching.

Can heat or assemble cold.

Not that strong, Yellow, PC based (polychloroprene cement) , basically Neoprene? most like Bostik 1222

Great for standard heels, leather to leather, putting zips in and anything that needs stitching.

Can heat or assemble cold.

Aquilim

130 Video Like Syntic. Use heat 80deg to activate extra strength. Dries clear when ready to assemble. Sets non tacky, Good for pregluing. Needs pressing, hammering not much good. Sounds like it could be tricky to use!

315 Video Like CDC. Dries clear when ready to assemble. Not so good on TPR or PU. Not ideal for soling. WTF? Doesn't need heat. Thin is best. Might be good for patching and zips?

315 Video Like CDC. Dries clear when ready to assemble. Not so good on TPR or PU. Not ideal for soling. WTF? Doesn't need heat. Thin is best. Might be good for patching and zips?

Shoe sole product determines which glue to use

Gluing basics

There are basically 2 types of glue, Yellow and Clear. If in doubt use Clear Glue.

I currently use CDC and Syntic Total. CDC for heels.

Thickness of Glue

Glue needs to run of the brush, if it is too thick it will go on too thick and will not spread nicely. Glue for patching can be slightly thicker.

Gluing soles

Put plenty of glue onto the brush then start in the middle and lay it on evenly, avoid over brushing (that’s where you brush or try to brush the glue around and its already starting to dry, often as the glue is getting spread too thinly. Glue shoes then soling. As the shoes are more likely to need two coats and it reduces the risk of getting glue on the shoe as you get them out of the way sooner. Let glue dry for 5min, and then reapply to those surfaces needing two coats. Leave to dry for another 5min before assembling.

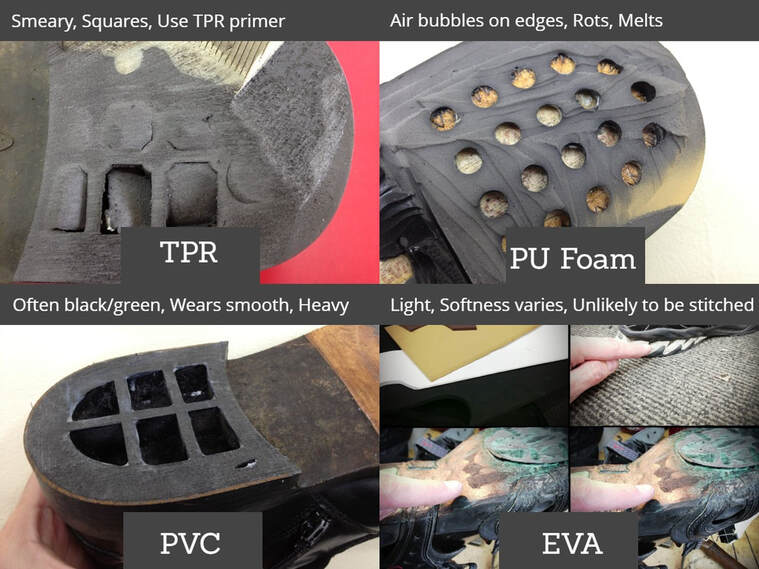

How do you tell them apart? It is often easier to think of what it is not, as this will narrow your choices

down. Tricky ones are PU Foam, PVC and TPR.

I currently use CDC and Syntic Total. CDC for heels.

Thickness of Glue

Glue needs to run of the brush, if it is too thick it will go on too thick and will not spread nicely. Glue for patching can be slightly thicker.

Gluing soles

Put plenty of glue onto the brush then start in the middle and lay it on evenly, avoid over brushing (that’s where you brush or try to brush the glue around and its already starting to dry, often as the glue is getting spread too thinly. Glue shoes then soling. As the shoes are more likely to need two coats and it reduces the risk of getting glue on the shoe as you get them out of the way sooner. Let glue dry for 5min, and then reapply to those surfaces needing two coats. Leave to dry for another 5min before assembling.

How do you tell them apart? It is often easier to think of what it is not, as this will narrow your choices

down. Tricky ones are PU Foam, PVC and TPR.

TPR

TPR/TPU, Thermoplastic Rubber, Thermoplastic Urethane

Smeary when ground. If you put solvent on to a rag and wipe black TPR, the rag will become black. Unlikely to have veneer on outside ... but sometimes does on harder TPR.

Think Budget cheap nasty, but often used on expensive as well. Flicky when ground, often has air bubbles in a bit from the edge, often has square holes in the heels and support lines across at the front, only visible when badly worn or once you have ground a lot off.

Use TPR primer. Renia yellow bottle. Wait 5min or longer if pourus looking. Then CDC or Syntic.

Smeary when ground. If you put solvent on to a rag and wipe black TPR, the rag will become black. Unlikely to have veneer on outside ... but sometimes does on harder TPR.

Think Budget cheap nasty, but often used on expensive as well. Flicky when ground, often has air bubbles in a bit from the edge, often has square holes in the heels and support lines across at the front, only visible when badly worn or once you have ground a lot off.

Use TPR primer. Renia yellow bottle. Wait 5min or longer if pourus looking. Then CDC or Syntic.

Polyurethane Foam - PU

Has little air bubbles on the outside which are more visible on sharp corners/edges.

Think Rieker and eccos, it rots, it splits and absorbs moisture. Grinds powdery when new and

then melts when older, Often has round holes in the heels and maybe shallow grooves across under the fore foot,

you can’t usually see the holes from the bottom of the sole, only once the upper is removed, maybe you

will see the heel holes from the bottom once you have ground a lot away.

Light weight.

Melts when rotten otherwise powdery.

Often Circles inside at heel.

Commonly used in moulded soles. Can be stiff or flexible.

CDC or Syntic.

Think Rieker and eccos, it rots, it splits and absorbs moisture. Grinds powdery when new and

then melts when older, Often has round holes in the heels and maybe shallow grooves across under the fore foot,

you can’t usually see the holes from the bottom of the sole, only once the upper is removed, maybe you

will see the heel holes from the bottom once you have ground a lot away.

Light weight.

Melts when rotten otherwise powdery.

Often Circles inside at heel.

Commonly used in moulded soles. Can be stiff or flexible.

CDC or Syntic.

PVC/Vinyl

Think Doc Martin, (greenish sole with Black randing) it wears smooth and shiny, comes in many densities

Chlorine smell when ground. Smeary/moist look. Often Squares inside at heel. Kinda melts as you grind it.

CDC or Syntic.

Chlorine smell when ground. Smeary/moist look. Often Squares inside at heel. Kinda melts as you grind it.

CDC or Syntic.

EVA

Soft, the mid sole of a running shoe. Unlikely to be stitched thru the sides. Easily confused with PU Foam.

Generally in NZ, EVA Caster is the firmer better quality product. EVA Asian is the softer poorer quality product. But you can get good and bad soft or hard.

Primer EVA 6 helps if using Clear glue esp. on Asian EVA. Allow to dry min 5min.

ORTEC or Clear 1-2 coats. Depending on how strong it needs to be. For example slipper vs Mens boot sole. If all the glue soaks in, add a second coat.

Generally in NZ, EVA Caster is the firmer better quality product. EVA Asian is the softer poorer quality product. But you can get good and bad soft or hard.

Primer EVA 6 helps if using Clear glue esp. on Asian EVA. Allow to dry min 5min.

ORTEC or Clear 1-2 coats. Depending on how strong it needs to be. For example slipper vs Mens boot sole. If all the glue soaks in, add a second coat.

Leather/Suede

Fibourous.

CDC or Syntic.

CDC or Syntic.

Leather reconstituted

Like chip board but its little bits of leather. Often used as rand/edging.

CDC or Syntic.

CDC or Syntic.

Microcellular Rubber

Soft rubber with air in it. Sort of softish. Dry powdery when ground.

CDC or Syntic.

CDC or Syntic.

Plastic Rand

Hard, try it with your finger nail.

CDC or Syntic.

CDC or Syntic.

Polypropylene

Really really hard, shinny.

If its a heel block both seam to work OK.

If its a midsole on a platform shoe, try to leave the leather covering ... otherwise might have issues gluing.

CDC. Meant to run a flame over it first. But seams to glue fine without.

If its a heel block both seam to work OK.

If its a midsole on a platform shoe, try to leave the leather covering ... otherwise might have issues gluing.

CDC. Meant to run a flame over it first. But seams to glue fine without.

Rubber

RubberPowdery when ground, think car tyre.

CDC or Syntic.

CDC or Syntic.

Sidi Soles - MX

|

Solid rubber with additives

TPR Primer-Yellow Bottle. Leave Primer 5 minutes CDC or Syntic. 2 coats. Yes sure we can glue a new set of soles onto your MX Boots, we use the SIDI Soles as they last really well where many others get chewed out by the foot pegs, we can also glue your exiting soles back on if they are still in good condition.

Gluing SIDI, Gaerne, Alpine Star, Fox1. TPR Primer onto Sole and Boot (as long as boot or sole is not porous!) 2. Clear glue then wait at least 2hrs 3. Clear glue then wait at least 30min 4. Assemble as per manual IF the boot or sole is porous DO NOT USE PRIMER you can still rub it with solvent and let dry before gluing if you think it needs it. |

FOX Instinct inserts

|

Wood

Splinters, grain, firewood. Not flexible.

CDC or Syntic.

CDC or Syntic.

Unit Sole - Micro

Dress unit, power unit.

Primer EVA 6 helps if having issues using clear glue.

CDC

Primer EVA 6 helps if having issues using clear glue.

CDC

Misc

Interesting further reading www.gem-chem.net/artpubsoles.html